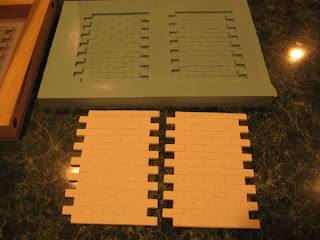

I ordered some mold making supplies from: http://www.smooth-on.com/ . I then cut out the flat parts of the pillar and trimmed them up so they would interlock. I made a small box and contact cemented the pcs to the bottom face up. I mixed up the mold making liquid and poured it in. After it set for a day (today) I pulled out the new mold, removed the masters, flipped the mold face up in the box to maintain the shape and poured in some Hydrocal Plaster .Here are the results.

I'll be using these all over my layout. It was a fast and useful project that I hope you can use too!

6 comments:

wonderful work, and like vulcan's previous post something everyone can use, yet never is clever enough to think of. keep 'em coming ... its stuff like this that goes a long way on a layout!

Great Job, Gizzmo!

Well written and good post. In order to make a longer lasting mold, I've read using gauze as a filler between coats of the rubber mold compound works well. Any thoughts since you will be making several? Also as you pour more "duplicates", I heard they tend to shrink slightly?

Well Dave this isn't the first time the gause sugestion has come up.I think the use of the gause started with making molds from latex. Its used in the building of layers because the latex is rather fraile.This "OOMO 25" I used seems to be tuff stuff. All I can add is that I've now cast 25 or more wall sections using this mold and its showing no sign of damage or loss of detail.As for the srinking,I haven't noticed any. the wall sections still mesh rather well. On a larger casting shrinkage may have an impact but theres no sign of any on these small ones.

I have made several molds from latex rubber and have used gauze or similar materials. It is much thinner and more fragile that what it looks like Gizzmo is using. That stuff looks very solid.

This is great, I may want to try something like this,

Thanks for the detailed info

Post a Comment