When the votes were finally tallied in August, the windmill won the honor of being the September Token Build. While many voted, three brave builders decided to tackle the challenge. David Baran, Jim M, and Vulcan all completed their builds and have agreed to share pictures of their progress here on the blog. While admiring their unique choices, and building expertise, its our hope as Token Builders that you can take some ideas and techniques home with you and use them on your own build.

As with most scratch-builds, the modelers first had to choose a prototype to model. Here in southern Texas, windmills are everywhere. Many are smaller than I had imagined they would be and served to bring water up from wells to troughs for livestock. I had always thought their was one standard windmill, but a quick image search on the internet came up with many different styles of windmills located throughout the country. Each participant chose one that best suited the style they were looking for and began their builds.

First, the modelers had to build the support structure for the windmills. All the different builds had this part in common as there didnt seem to be many styles that diveated from the norm. In most cases, a template was used to help keep things centered and squared.

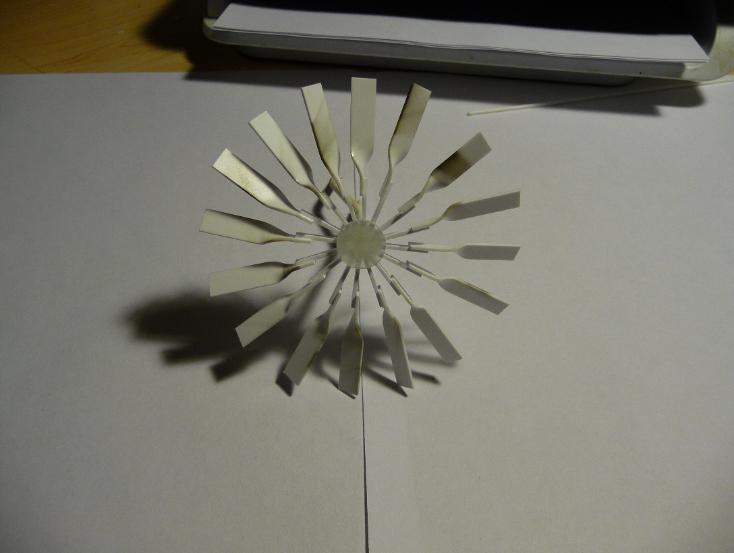

Next came the most recognizable feature of all windmills: the blades. This would also be the most difficult and time consuming part of the build. Not only did the blades have to be cut out individually, but they also had to be arranged in a symmetrical pattern, evenly spaced, and at a slight angle in order to spin in the wind. Once again, each modeler chose their own technique to manufacture this part of the build. As you can see, their patience and skill paid off.

Next came the most recognizable feature of all windmills: the blades. This would also be the most difficult and time consuming part of the build. Not only did the blades have to be cut out individually, but they also had to be arranged in a symmetrical pattern, evenly spaced, and at a slight angle in order to spin in the wind. Once again, each modeler chose their own technique to manufacture this part of the build. As you can see, their patience and skill paid off.

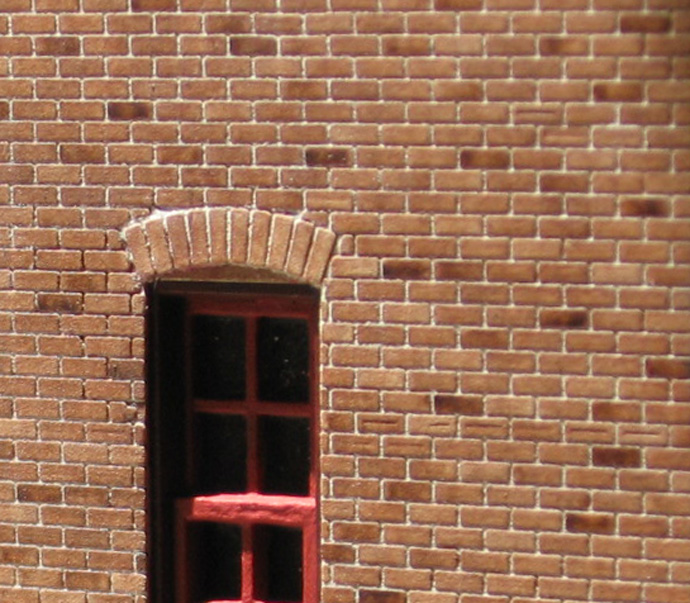

With the appropriate weathering and paint applied, the builds were ready to be photographed for their debuts on the OGRR forum's Scenery Section. Soon they found places on their owner's layouts and will forever be posted here for others to admire and learn from. As with every post here on the Token Three Railer, we thank the modelers who participated and hope to see more from them on future builds. And if you are up for a healthy dose of scratch-building fun, check out the latest Token Poll and see if one of the choices might be of interest to you. The community of modelers associated with this blog are anxious to see your work!

With the appropriate weathering and paint applied, the builds were ready to be photographed for their debuts on the OGRR forum's Scenery Section. Soon they found places on their owner's layouts and will forever be posted here for others to admire and learn from. As with every post here on the Token Three Railer, we thank the modelers who participated and hope to see more from them on future builds. And if you are up for a healthy dose of scratch-building fun, check out the latest Token Poll and see if one of the choices might be of interest to you. The community of modelers associated with this blog are anxious to see your work!